The maintenance squadron consists of four flights: Flight Inspection, Flight Intervention, Flight Engines, Flight Support. Each flight has his own storage and specific task and contributes directly or non-directly to realize the F-16 flight plan.

Flight Inspection

Every 300 flight hours (or about after every year and four months) a detailed maintenance is planned for each F-16.

The Flight Inspection is subdivided into two main areas; the Docks and the Backshops. Both are controlled by the technical management:

Docks:

Each dock always has one aircraft in major maintenance, performing a 300 flight hours inspection. For this inspection an aircraft is about 35 days out of service, often prolonged because of extra inspection (1800 flight hours inspection,…) and modifications.

Backshops:

- the Aircraft Cleaning Facility ensures that every 50 flight hours a F-16 gets cleaned, is being checked on corrosion and essential parts will be extra lubricated

- the Paintshop and sealers are responsible for paintwork, sealing, works of composite and repairs on the aircraft and parts of the aircraft. They also have artists responsible for painting the special squadron tails.

- The maintenance and/or repair of the wheels, brakes and fuel tanks (wing tanks and centre line tanks) is done by the Brake unit.

- The Elec section is responsible for all electrical works on the aircraft and his parts. They are also essential in conducting modifications on the aircraft like placing new wirings, power supplies and adapting plugs.

- The Non Destructive Inspection (NDI) disposes of all kinds of techniques to early detect cracks, not yet visible to the eye. The aircraft, as well as parts of, it are regularly inspected.

- The Hydraulic Shop does the maintenance, inspections, repairs and tests of all hydraulic components. They manufacture their own “tubes” tailored to the aircraft’s needs by means of the original blueprints.

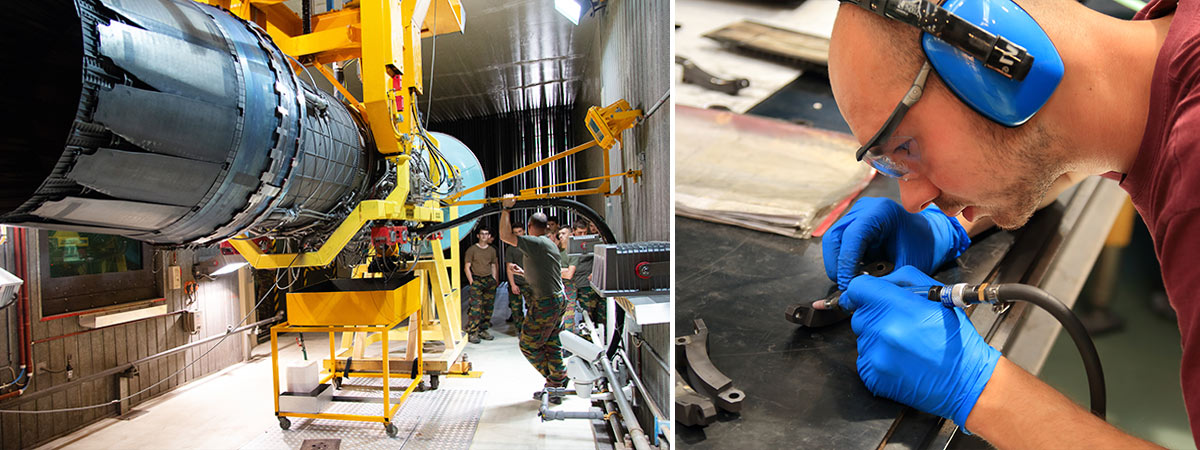

- The sheet metal workers are the bodywork specialists of the F-16. Besides small repairs, they are also in charge of structural changes (extra holes, extra brackets, extra supports)

- A very important extra daily task of the Flight Inspection is the organization of the crash car and its team. This “Crash Car Team” is on call from the start of the flying window until closure to support the Fire Fighters when an aircraft in emergency (with possible technical problems) is coming in to land.'

Flight Intervention

The flight Intervention is subdivided into three different specialties (Airframe, Elec and Engine), a command structure, a technical management and storage.

The main objective is to ensure maximum serviceability of the fleet. The three subdivisions; Airframe, Elec and Engine, are responsible for preventive maintenance (inspections and/or small maintenance) and corrective maintenance (repairs or interventions).

Besides the main objective, the Flight Intervention is also involved in modifications or supporting other sections in performing modifications. The de-composing and composing of all kinds of compartments followed by thorough inspections is often five times the work as the modification itself.

The Repair Chief is the one delegating and assigning specialists in teams of two to several locations (flightline/shelter) in order to loose minimal time to make the aircraft serviceable as quick as possible again..

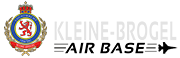

Flight Engines

Every 200 flight hours, the F-16 engine needs to be removed and has to undergo a “phase-inspection”. This inspection, as well as other engine inspections, are the responsibility of the Flight Engines.

To fulfill this task, the Flight Engines is subdivided into several specialisms:

- Dock Repair: the technicians dismantle the engine into several small modules, they check the connections to the engine and repair them if needed.

- Dock Module: these technicians are specialized in dismantling the modules, each being inspected and repaired if needed.

- Dock Boro: inaccessible parts of the engine are inspected by means of boroscopy.

- Test Bench: every engine needs to be thoroughly tested before being reinstalled in the aircraft.

- Soap: after every flight, a motor oil sample is taken and analyzed in order to check possible abnormal wear.

Flight Support

The Flight Support is subdivided into three specialized branches:

- Ground Support Equipment section (GSE): corrective and preventive maintenance of all ground equipment. Eg hydraulic test benches, power groups, cooling groups, test sets, bomb trailers, tow bars, aircraft ladders, …

- Survival section: maintenance and inspection of parachutes, G-suits, pilot helmets and survival packages of the ejection seat. They also clean, sanitize and repair the pilot’s material after every flight.

- Workhouses (welders and turners): they are of the entire 10WTac’s service to do all welding and lathe tasks/repairs.